Clique para ampliar

Discover our story

Clique para ampliar

At the end of the 19th century, Alentejo relied on agriculture and cereal production, with wheat as its main source of wealth and a symbol of rural life. Bread, olive oil and wine sustained both the daily table and the identity of local communities.

Before 1926, Viana do Alentejo registered ten companies dedicated to milling, trade and local distribution. Vasques Fadista Limitada / Moinhos de Santo António combined cereal milling with an olive press, reflecting a family heritage that mirrored the region’s economic fabric.

Clique para ampliar

In 1885, a royal charter issued by King Luís authorised the sale of the lands of Horta de Santo António and Ferregial, belonging to the Convent of Bom Jesus in Viana do Alentejo, to Francisco Joaquim Vasques Fadista (1858–1931) for 680,000 réis, paving the way for the establishment of the family’s mill and olive press. After his death in 1931, two of his sons continued the activity, formalising the company Vasques Fadista, Lda. that same year.

Clique para ampliar

Clique para ampliar

Clique para ampliar

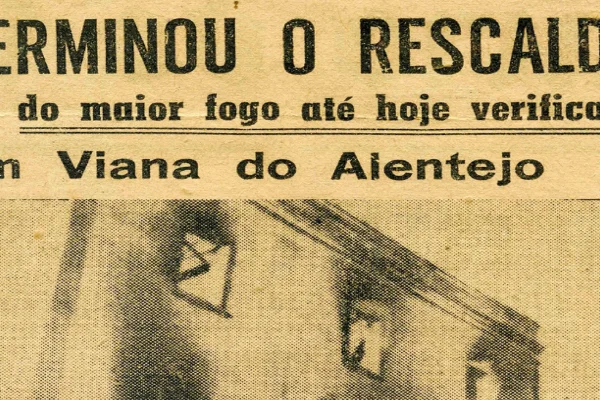

On 16 November 1946, the Mill suffered a devastating fire that completely destroyed the factory, leaving a deep mark on the community and receiving extensive media coverage. The bravery of Jesuíno Simões stood out: living next door to the mill, he tirelessly carried out eighty-kilogram flour sacks, two at a time, saving part of the production.

Two and a half years later, at the inauguration of the new Moinhos de Santo António, the owners invited all those who had helped fight the fire to a commemorative lunch.

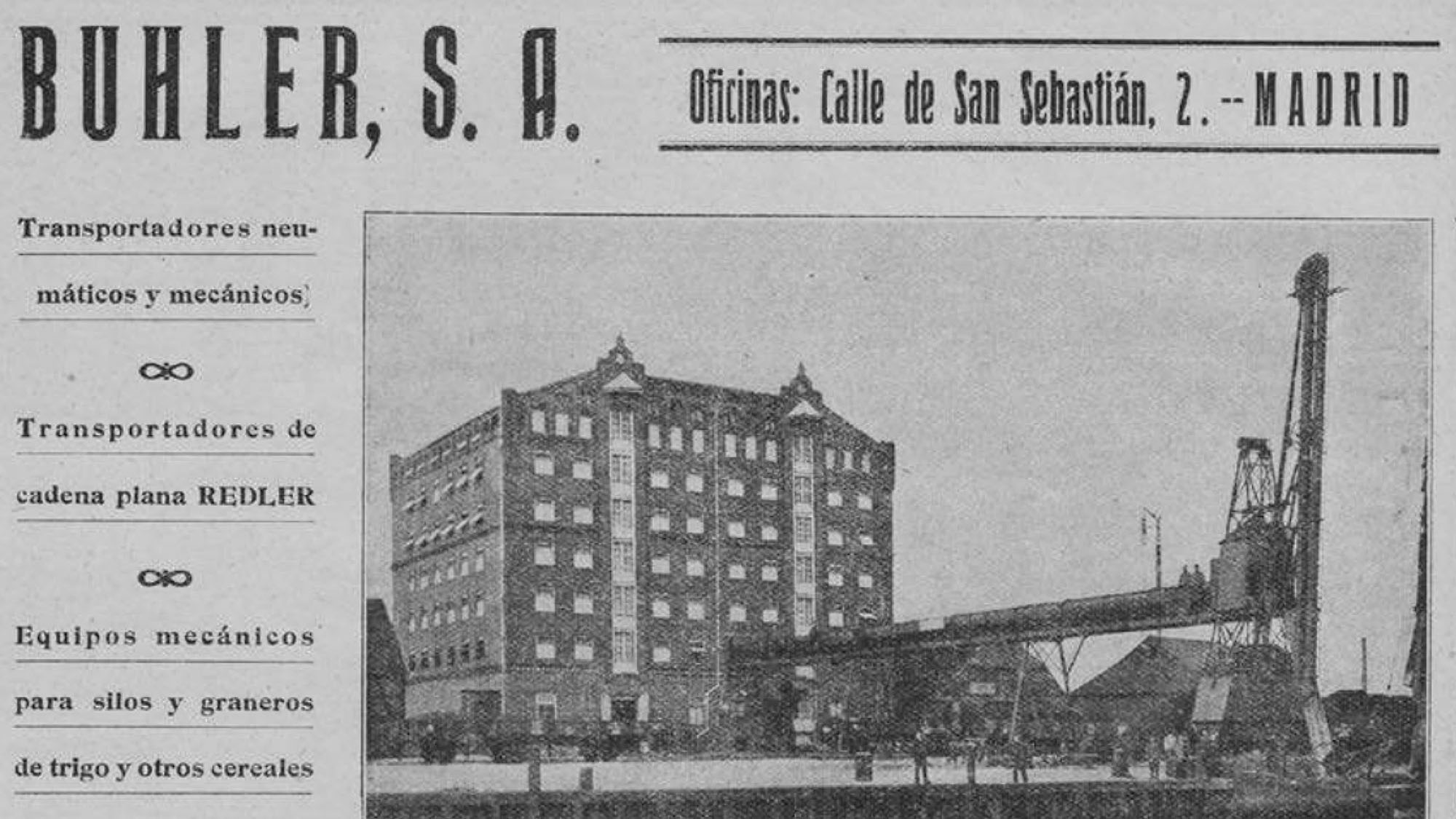

In April 1949, the new Moinhos de Santo António were inaugurated, aligned with modern technology and improved efficiency. Built using the Austro-Hungarian system, they incorporated state-of-the-art machinery with a production capacity of 14,300 kg/day, identified with the “Bühler System” seal.

The mill remained in operation until the 1980, when Fratejo acquired the land and installed new units for animal feed production. Opened in 1990, the facility closed in 2002.

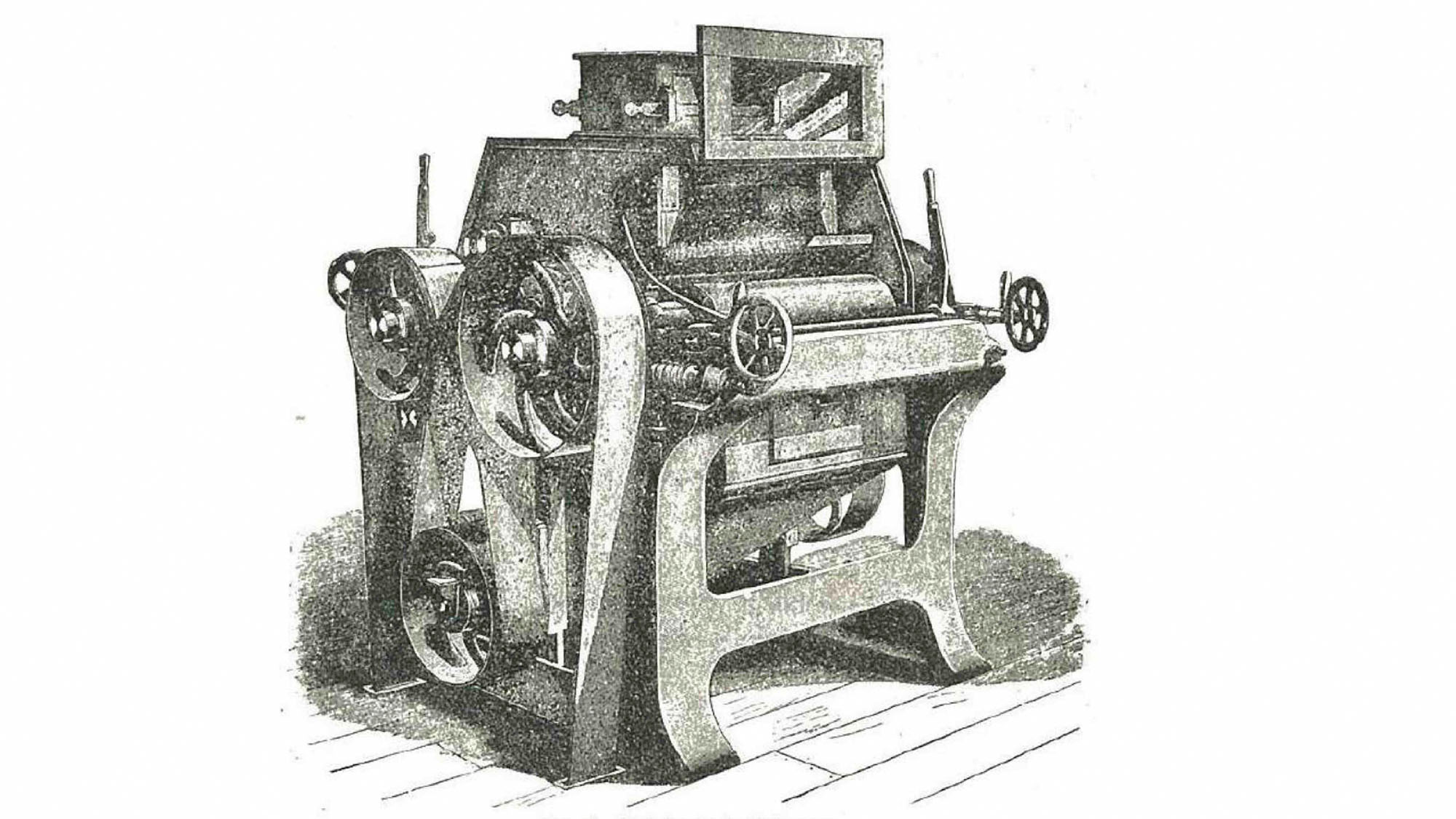

In the 19th century, the milling industry evolved from stone grinding wheels to steel roller mills, enabling finer and higher-quality flours.

Hungary led this innovation by developing a gradual milling model based on crushing and sieving, as well as cleaning, transporting and ventilating the wheat.

Bühler, a Swiss company, became one of the main promoters of the system.

With branches in Madrid and Lisbon since 1917, it equipped numerous Portuguese mills throughout the 20th century.

In gradual milling, the grains pass through mills with three functions:

- Break rollers: crush the grain and separate bran and germ, producing black flour and middlings.

- Reduction rollers: refine the middlings, with alternating passages through sieves.

- Converting rollers: transform the final middlings into fine flour.

Sieving is carried out in Plansichters and Sassores, which classify particles by size and density, returning the semolina to the rollers until the ideal flour is obtained. The Plansichter, patented by Károly Haggenmacher in 1887, revolutionised the process by allowing up to eight products to be classified simultaneously.

In 2023, the revitalisation works of Moinhos de Santo António began. The project, designed by architect Gonçalo Carvalho, transforms the historic building into a hotel that combines the charm of industrial architecture with modern comfort and sophistication, preserving industrial features and integrating contemporary elements.